Precision and Efficiency: A Deep Dive into the Mazak Quick Turn 250 MSY CNC

The Mazak Quick Turn 250 MSY CNC is a cutting-edge solution at the forefront of modern machining technology. In this blog post, we’ll explore the key features, capabilities, and benefits that make it a game-changer in CNC machining.

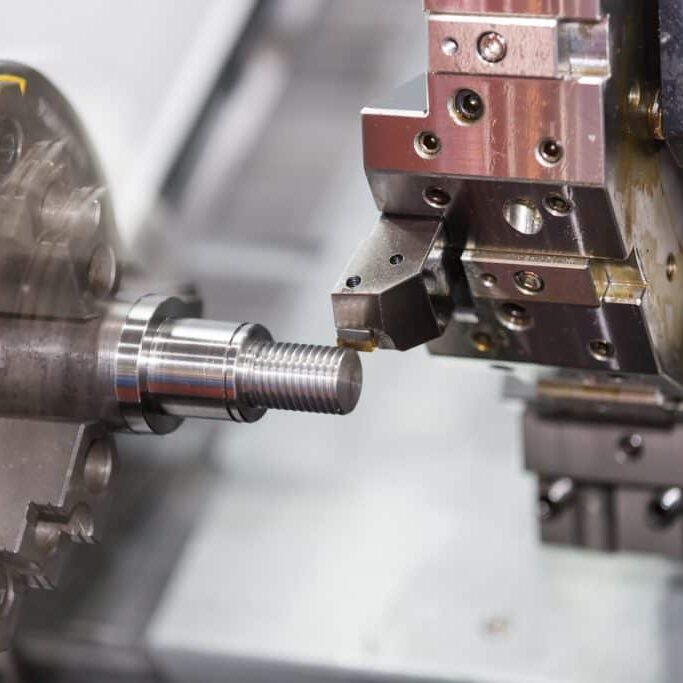

The Mazak Quick Turn 250 MSY is a state-of-the-art CNC turning center designed to deliver high-performance machining with precision and versatility. Equipped with advanced features, this machine is suitable for a wide range of applications across various industries.

Key Specifications:

• Maximum Swing: 26.60 inches.

• Maximum Machining Diameter: 14.760 inches.

• Maximum Spindle Speed: 4,000 rpm.

• Turret Number of Tools: 12.

• Main Spindle Chuck Size: 10 inches.

• Second Spindle Chuck Size: 6 inches.

• Feed Axes:

- Travel (X-Axis): 9.00 inches.

- Travel (Y-Axis): 4.00 inches.

- Travel (Z Axis): 22.63 inches.

- Travel (W Axis): 23.00 inches.

Multi-Tasking Capabilities:

One of the standout features of the Mazak Quick Turn 250 MSY is its multi-tasking capabilities. With simultaneous machining operations on the main and sub-spindle, coupled with the Y-axis functionality, this CNC machine allows for complex and intricate part production in a single setup.

Integrated Y-Axis for Enhanced Versatility:

The inclusion of a Y-axis expands the machining possibilities by enabling off-centre milling, drilling, and tapping operations. This reduces setup time and enhances the overall efficiency of the machining process.

Smooth and Precise Machining:

The Mazak Quick Turn 250 MSY is engineered for precision. Its high spindle speeds and rapid traverse rates contribute to smooth and accurate machining, ensuring that even the most intricate details of a workpiece are crafted with utmost precision.

Increased Productivity:

The combination of multi-tasking capabilities and the Y-axis functionality significantly reduces cycle times, leading to increased productivity. Aaron Machine Shop can produce more complex parts in less time, contributing to overall operational efficiency.

Improved Quality and Consistency:

The Mazak Quick Turn 250 MSY is renowned for precision machining. The machine’s ability to maintain tight tolerances and produce high-quality finishes ensures that each workpiece consistently meets the required standards.

Cost Savings:

The Mazak Quick Turn 250 MSY helps Aaron Machine Shop save on labour costs and reduce material waste by streamlining operations and minimizing the need for multiple setups. The result is a more cost-effective manufacturing process. These savings are then passed on to our customers.

Real-World Applications:

- Aerospace Industry

The Mazak Quick Turn 250 MSY is utilized in the aerospace industry for manufacturing critical components that demand precision and reliability.

- Medical Device Manufacturing

This CNC turning center is contributing to the production of intricate and precise components in the medical device manufacturing sector.

The Mazak Quick Turn 250 MSY CNC is undeniably a powerhouse in CNC machining. Its advanced features, multi-tasking capabilities, and precision machining make it indispensable for manufacturers across various industries. As technology continues to advance, the Mazak Quick Turn 250 MSY stands as a testament to the commitment to innovation and excellence in modern machining.

Aaron Machine Shop is proud of having some of the most sophisticated CNC machines available. This machine is incredibly accurate, fast, and industry-diverse in its capabilities.

If you are interested in having our team of professionals manage your project(s), please contact Aaron Machine Shop today.

P: (403)255–2425

Bay C, 7008 5 ST SE, Calgary, AB T2H 2G3

Share this article

Types of Metals Used in Welding

During the welding process, the properties of the metal being welded need to be taken…

The Differences Between Welding and Metal Fabrication

If you work in an industry that requires the use of a lot of metal,…

How to Find a Metal Supplier for Your Next Project

For innovators, artists, inventors, creators of cool stuff and DIY fanatics, Aaron Machine Shop is…